From Storage Facility to Building And Construction Site: Maximize Operations with Stacking Conveyors for Sale

From Storage Facility to Building And Construction Site: Maximize Operations with Stacking Conveyors for Sale

Blog Article

Optimize Reusing Output With Stacking Conveyors: a Vital Devices Solution

As the need for recycling remains to grow, finding effective services to optimize result becomes progressively important. One such service that has acquired popularity in the reusing market is the use of stacking conveyors. These functional tools deal many advantages, from boosted performance to boosted safety and security. In this conversation, we will check out the numerous types of stacking conveyors, their applications in reusing, elements to think about when selecting the best conveyor, and important tips for maximizing reusing outcome. If you're looking to boost your recycling procedures and accomplish greater degrees of effectiveness, this is a subject you won't want to miss.

Advantages of Piling Conveyors

Piling conveyors provide countless advantages in the recycling market, boosting performance and productivity while lessening manual work and decreasing operational expenses. Among the key benefits of piling conveyors is their capacity to stack products in an arranged and space-saving fashion. By stacking products up and down, these conveyors enhance using readily available area, enabling for a greater volume of products to be stored and transferred. This is specifically beneficial in reusing facilities with limited space.

Stacking conveyors additionally add to boosted performance in reusing procedures. By effectively stacking products, these conveyors make it possible for quicker and extra streamlined processes, reducing the time needed for arranging and storage space. This, subsequently, permits a higher throughput of materials, bring about enhanced overall performance.

Moreover, using piling conveyors can dramatically lower functional prices. With automated piling systems, the need for extra manpower is lessened, resulting in reduced labor costs. Furthermore, by maximizing space use, these conveyors enable reusing centers to optimize their output without the need for costly expansions or extra storage space facilities.

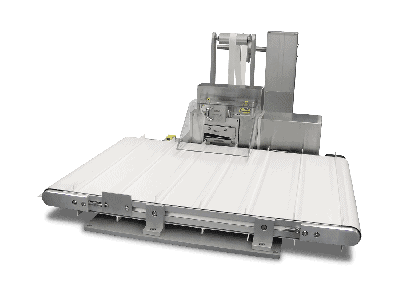

Kinds of Stacking Conveyors

One important element to consider when discovering the benefits of piling conveyors in the recycling sector is comprehending the various sorts of piling conveyors offered. These conveyors are necessary in making best use of reusing outcome by efficiently relocating and stacking materials.

The first kind of piling conveyor is the radial piling conveyor. Radial piling conveyors are commonly used in applications where adaptability and ability to move are essential.

The 2nd type is the fixed piling conveyor. As the name recommends, this conveyor is stationary and does not have the ability to rotate. It is usually made use of in circumstances where products need to be piled in a straight line, such as in a sorting or processing facility.

A third kind of piling conveyor is the telescopic piling conveyor. This conveyor has the capability to prolong and pull back, permitting it to reach greater distances. It is typically utilized in applications where materials need to be piled at different heights or where room is restricted.

Applications of Piling Conveyors in Recycling

Piling conveyors play a vital role in the reusing sector, facilitating effective product motion and piling to take full advantage of recycling result. These versatile machines are widely used in numerous applications within the reusing process.

One of the key applications of stacking conveyors in recycling is in the sorting and separation phase. After recyclable materials are accumulated, they need to be sorted and separated to optimize their value. Piling conveyors can be used to transport different sorts of products, such as paper, plastic, steel, and glass, to designated sorting locations. They allow continuous and smooth material activity, guaranteeing an efficient sorting process.

One more essential application of piling conveyors remains in the storage space and stockpiling of recyclable products. When materials have been sorted, they need to be stacked in an organized way for further processing or transportation. Stacking conveyors enable the creation of compact and neat stockpiles, maximizing storage space and helping with very easy access for succeeding phases of the reusing process.

Moreover, stacking conveyors are commonly used in the loading and dumping of recyclable materials. They enable the smooth transfer of materials in between various stages of the reusing procedure, such as from trucks to arranging lines or from arranging lines to storage locations. This efficient product motion minimizes downtime and increases total productivity.

Aspects to Take Into Consideration When Selecting a Stacking Conveyor

When selecting a piling conveyor for your reusing operation, it is important to take into consideration a number of aspects to guarantee optimal performance and efficiency. The very first factor to consider is the dimension and weight of the materials being conveyed. It is crucial to pick a stacking conveyor that can deal with the certain materials you are functioning with. Additionally, the size and elevation of the conveyor should be considered to ensure it fits within your facility and can get to the wanted piling elevation.

One more crucial element to consider is the rate and capacity of the stacking conveyor. The conveyor needs to be able to manage the required volume of other products without creating traffic jams or delays in the recycling procedure. It is also essential to take into consideration the power source and energy intake of the conveyor to guarantee it aligns with your sustainability goals.

Last but not least, consider the security attributes of the piling conveyor. Try to find attributes such as emergency stop buttons, safety guards, and warning signs to secure employees and stop accidents.

Tips for Taking Full Advantage Of Reusing Output With Stacking Conveyors

Primarily, normal maintenance is critical for the smooth procedure of piling conveyors. This consists of routine examinations of motors, rollers, and belts to recognize and resolve any kind of possible problems before they cause major disturbances - stacking conveyors for sale. In addition, lubrication and cleansing must be carried out to stop build-up and make sure ideal performance

Appropriate training and education of operators is an additional key consider maximizing reusing output. Operators must be fluent in the operation of stacking conveyors and familiar with ideal practices for taking care of different types of products. Clear interaction networks and efficient coordination between drivers and sorting workers are likewise important to make certain a seamless flow of recyclables.

One more idea for taking full advantage of recycling output is to optimize the layout and configuration of piling conveyors. This involves considering factors such as the size and weight of materials, the quantity of incoming recyclables, and the offered area. By tactically placing the conveyors and making use of extra tools like arranging magnets and screens, centers can simplify the recycling procedure browse around these guys and rise output.

Lastly, data surveillance and analysis can provide beneficial understandings into the efficiency of stacking conveyors - stacking conveyors for sale. By tracking metrics such as downtime, throughput, and maintenance costs, centers can identify locations for enhancement and apply targeted options to enhance effectiveness and productivity

Final Thought

Finally, piling conveyors are crucial equipment for maximizing recycling outcome. They offer numerous benefits, such as raised efficiency and reduced labor costs. Different kinds of piling conveyors accommodate various recycling applications, giving flexibility and adaptability. When choosing a stacking conveyor, aspects such as capacity, resilience, and size need to be considered. By carrying out stacking conveyors and following correct tips, recycling facilities can considerably increase their output and add to a more lasting future.

In this discussion, we will certainly check out the various types of piling conveyors, their applications in recycling, aspects to consider when selecting the right conveyor, and beneficial suggestions for maximizing reusing outcome. One of the main benefits of stacking conveyors is their capability to pile products in an organized and space-saving way.The initial type of stacking conveyor is the radial stacking conveyor.A 3rd type of piling conveyor is the telescopic stacking conveyor.In conclusion, stacking conveyors are crucial equipment for optimizing reusing result.

Report this page